Written by Emliy from Twothousand Machinery

As the growing of repaid economy and society, blast chillers/freezers have become an essential feature of the modern professional kitchen. By reducing the temperature of food quickly, they offer the responsible for organizing work in the kitchen indispensable advantages in terms of hygiene, product flavor and appearance.

Definition:

Blast chillers/freezers is a professional chilling/freezing and storing tool for all kinds of frozen food, like: mousse, cake, quick-frozen dumpling, Tangyuan or even steamed burn.

It’s used for cooling the food temperature in short time, so to keep food avoiding the loss of nutrition, also tasting fresh; mainly be used for commercial purpose.

Blast chillers are able to reduce food at core temperature from + 90 'C to + 3'C within 90 minutes;

Blast freezers are able to reduce food at core temperature from + 90 'C to -18 'C within 240 minutes.

Main Parameter:

TT-BF3: 3 layers,

Chilling capacity: in 90 minutes for 8 kg food;

Freezing capacity: in 240 minutes for 3 kg food

TT-BF5: 5 layers,

Chilling capacity: in 90 minutes for 18 kg food;

Freezing capacity: in 240 minutes for 12 kg food

TT-BF8: 8 layers,

Chilling capacity: in 90 minutes for 25 kg food;

Freezing capacity: in 240 minutes for 16 kg food

TT-BF11: 11 layers

Chilling capacity: in 90 minutes for 36 kg food;

Freezing capacity: in 240 minutes for 24 kg food

TT-BF15: 15 layers

Chilling capacity: in 90 minutes for 55 kg food;

Freezing capacity: in 240 minutes for 36 kg food

Operation:

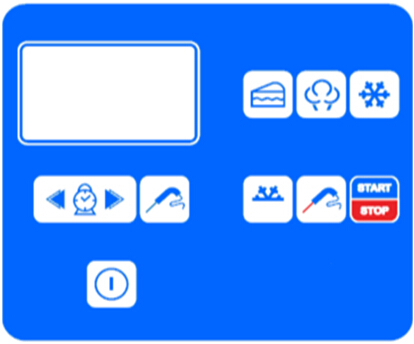

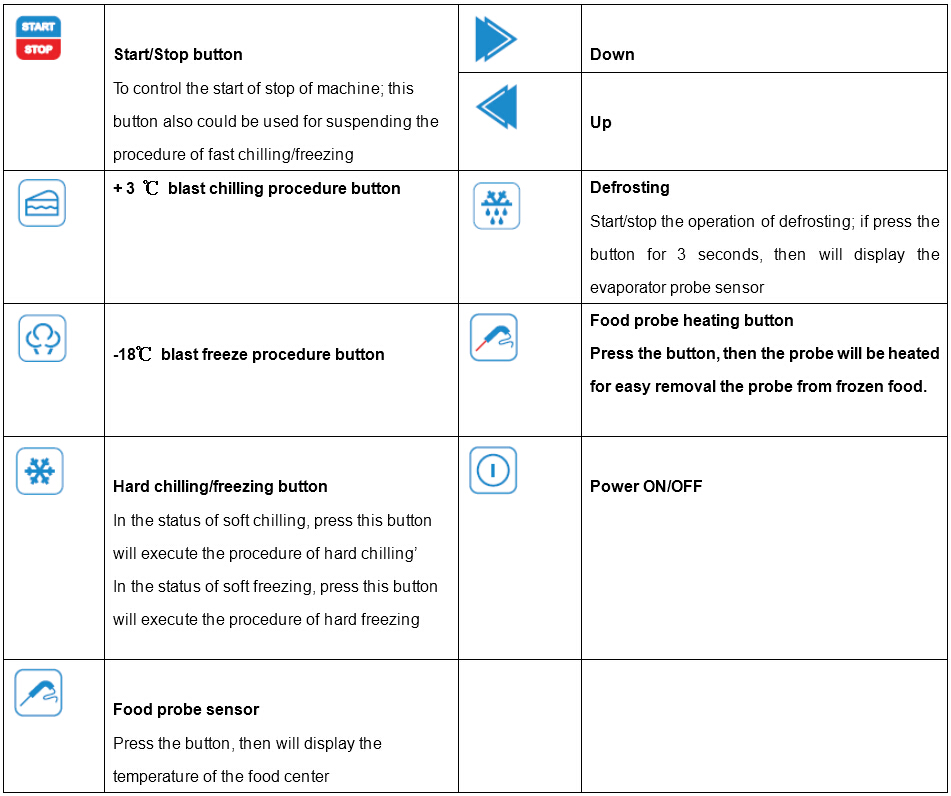

Control Panel:

Tips:

How to choose blast chilling/freezing procedure:

Press button, choose +3ºC soft chilling procedure; then press

button, choose +3ºC soft chilling procedure; then press button, will turn to +3ºC hard chilling procedure;

button, will turn to +3ºC hard chilling procedure;

Press button, choose -18ºC soft freezing procedure; then press

button, choose -18ºC soft freezing procedure; then press button, will turn to -18ºC hard freezing procedure;

button, will turn to -18ºC hard freezing procedure;

Features

1. High density polyurethane foam insulation which is CFC and HCFC free

2. 304 stainless steel material with excellent finish

3. Core temperature probe

4. Constructed to meet HACCP regulations

5. Chill from +90°C to +3° C in 90 minutes

6. Freeze from +90°C to -18°C in 240 minutes

7. 1 year warranty on parts and labor

Benefits

1. Rapidly decrease the temperature of food, minimizing bacteria growth

2. Implementing a cook and chill process will lead to better management of inventory

3. Work with hard chill, soft chill, hard freeze and soft freeze for excellent versatility

Caution:

1. Don’t open the door during chilling/freezing procedure finish

2. To avoid the food be covered or by plastic wrap

3. Don’t use the tray or container more than 65 mm depth.

4. Don’t stack the food.

5. Pls use aluminum of stainless steel tank for food, but do not with the cover.

Comments